Anti-skid floor coating is a safety-oriented epoxy-based coating system designed to reduce slip hazards in areas exposed to water, oils, chemicals, or frequent movement. By incorporating carefully graded anti-slip aggregates into the epoxy matrix, the coating creates a textured surface that enhances traction and minimizes the risk of slips and falls.

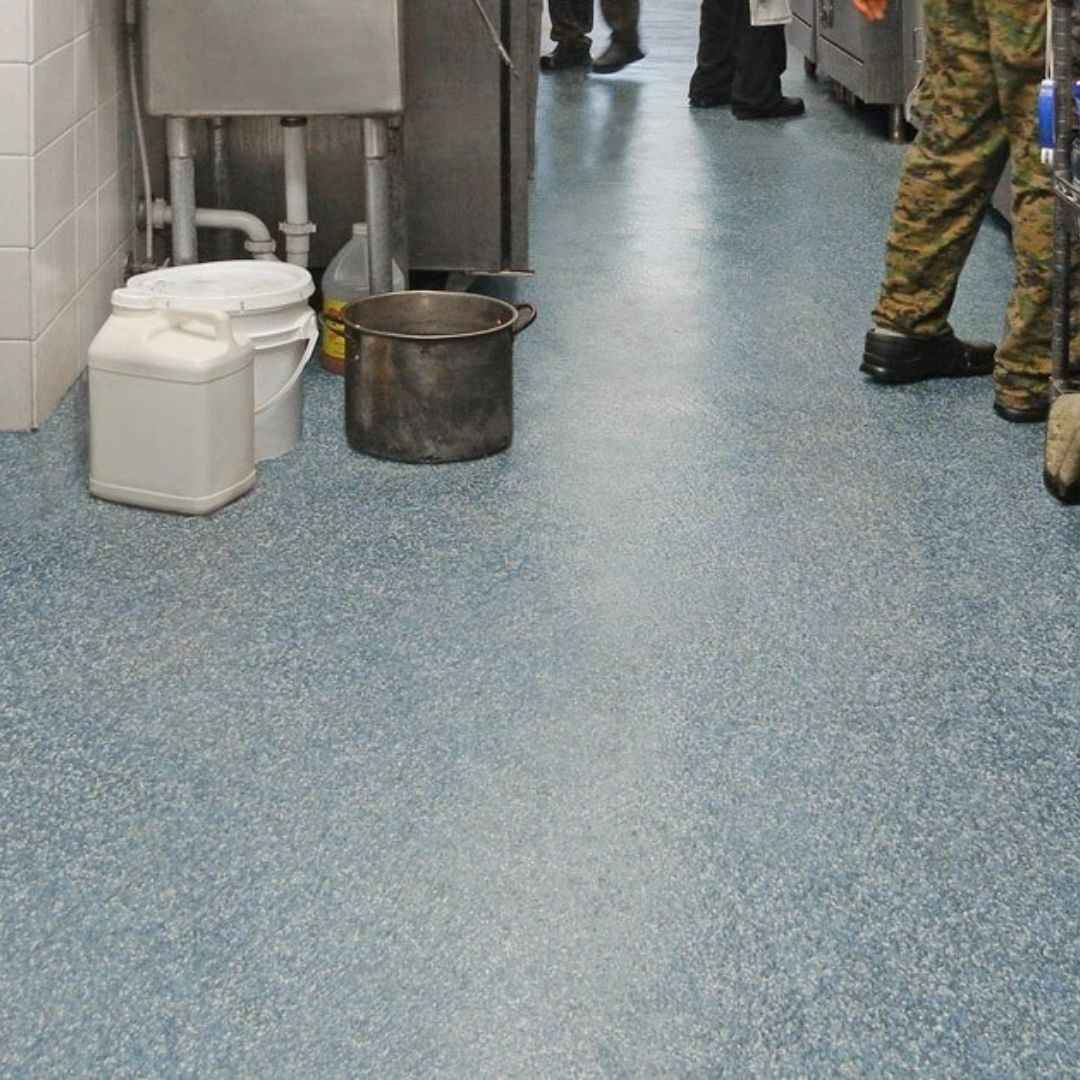

Built on a high-strength epoxy resin base, anti-skid floor coatings provide excellent resistance to abrasion, chemicals, oils, and mechanical stress. This makes them suitable for environments where safety and durability are equally critical, such as industrial facilities, commercial kitchens, parking structures, and processing areas.

The level of slip resistance can be customized to suit operational risk levels, ranging from moderate texture for general work zones to aggressive anti-skid finishes for high-risk areas. The seamless, joint-free coating prevents dirt accumulation and supports hygiene standards in regulated industries.

Installation involves professional surface preparation, epoxy priming, controlled broadcasting of anti-slip aggregates like quartz or silica, and sealing with a high-performance epoxy topcoat. Available systems include textured epoxy coatings, quartz-filled anti-skid systems, and heavy-duty non-slip epoxy screeds engineered for demanding applications.

Anti-skid floor coatings are suitable for both industrial and commercial spaces where safety, cleanliness, and durability are essential. With routine cleaning and periodic recoating, the coating maintains consistent slip resistance and delivers long-term performance.

Copyright © Aneeta Chemical Pvt. Ltd. All Rights Reserved.