As a professional Epoxy Flooring Applicator, we specialize in the precise application of high-performance epoxy flooring systems for industrial, commercial, and residential environments. Our work focuses on correct surface preparation, accurate material application, and long-term floor performance under demanding conditions.

We apply a wide range of epoxy flooring systems including self-leveling, heavy-duty, anti-slip, anti-static, chemical-resistant, and decorative epoxy solutions. Each system is selected and applied based on site conditions, usage patterns, and industry-specific requirements to ensure optimal results.

Our epoxy flooring application services are designed to enhance durability, safety, and appearance while supporting efficient operations. From factories and warehouses to cleanrooms and commercial interiors, our applied epoxy systems deliver reliable performance, clean finishes, and long service life.

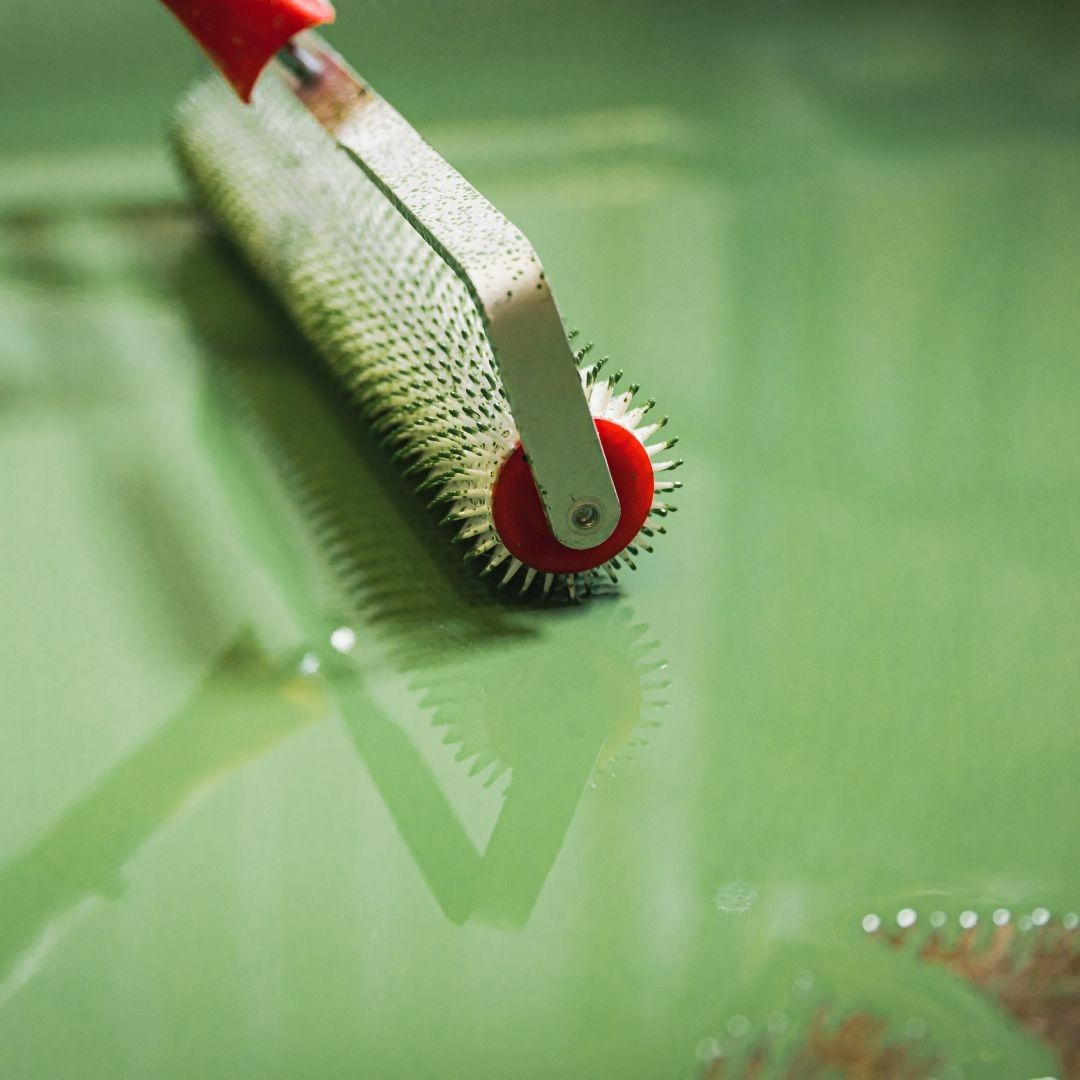

Our epoxy flooring applicator services follow a structured and quality-driven process. We begin with site inspection and surface evaluation, followed by mechanical preparation using grinding or shot blasting to ensure strong bonding.

Epoxy materials are applied in controlled layers based on system requirements, including primer, build coats, and protective topcoats. Each stage is monitored for thickness, curing, and surface quality to ensure long-term performance.

Copyright © Aneeta Chemical Pvt. Ltd. All Rights Reserved.